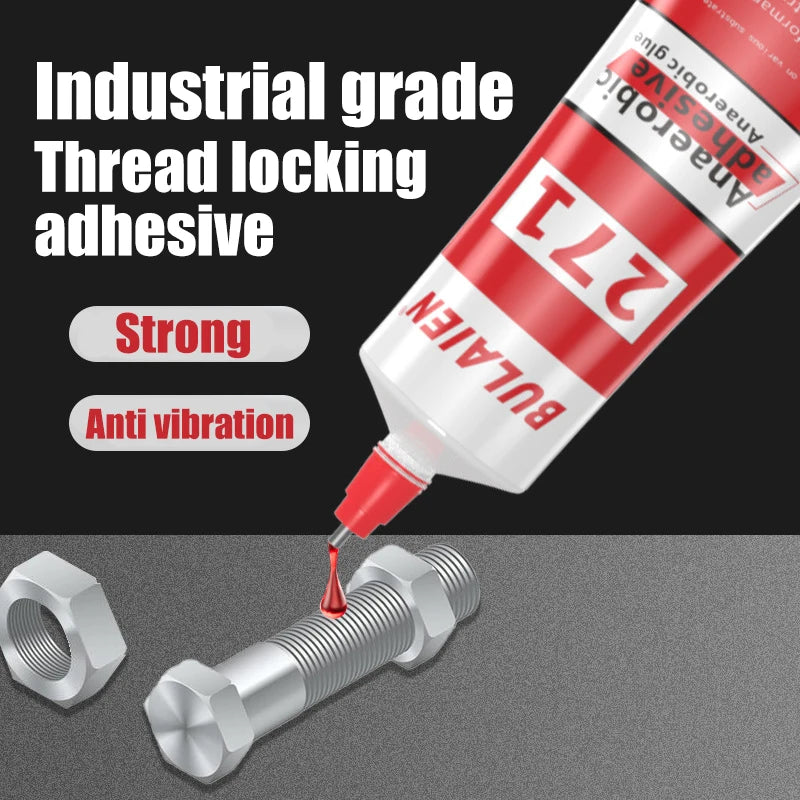

50ml Threadlocker Screw Glue Quickly Cured Thread Locking Agent Anaerobic Adhesive Corrosion-Resistant Anti-Loosening Glue

SPECIFICATIONS

Capacity: 50ml

Certification: REACH

Hign-concerned Chemical: None

Material: other

Type: Liquid Glue

Name: Thread Lock Anaerobic Adhesive

Pre-treatment to clean the surface of the assembly to ensure that there is no residual oil, grease, such as motor oil, rust oil, etc., most surfaces do not need to carry out special pre-treatment, for the bonding of the substrate, you need to cooperate with the accelerator pre-treatment. Gluing:Take appropriate amount of the product and apply it evenly on the threaded surface. Deglueing:The overflow of glue will not be cured, just wipe it off.

Model: 222 thread locking adhesive

Specification: 50ml

Special effects: low strength, detachable, anti loosening

Viscosity: 500~3000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 1.5~11.5 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Description: Used for most metal surfaces and can be disassembled with ordinary tools. Used for locking and sealing M2-M12 threads. The best effect is achieved when applied to fasteners with a diameter of no more than 1/4 #, with a certain degree of lubricity to achieve precise clamping load.

Model: 242 thread locking adhesive

Specification: 50ml

Special effect: medium strength - thixotropic viscosity

Viscosity: 500~3000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 2~23 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Description: Universal type, thixotropic viscosity; Used for locking and sealing M6-M20 threads. Can be used for tool disassembly and has a certain degree of lubricity to achieve precise clamping load.

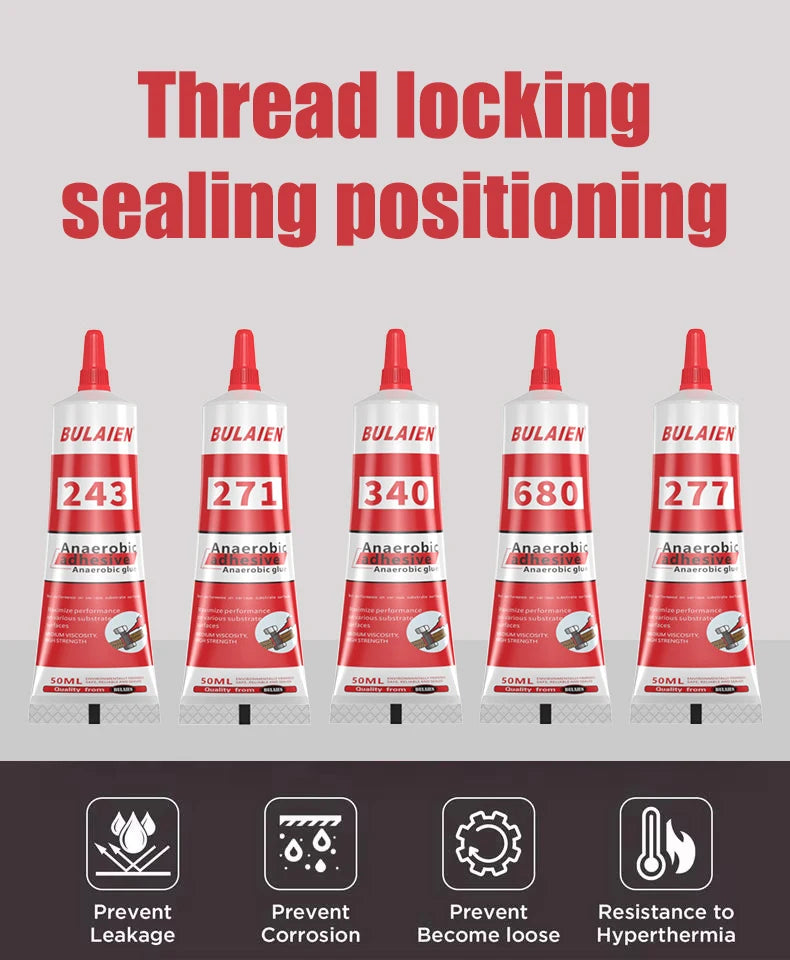

Model: 243 thread locking adhesive

Specification: 50ml

Special effect: medium strength - thixotropic viscosity

Viscosity: 1500~4000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 2~23 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Description: Fast curing, suitable for inert surfaces, good oil tolerance. Easy to disassemble,

Can be used on work surfaces with slight oil pollution. Used for M20 Locking and sealing of the lower thread.

Model: 262 thread locking adhesive

Specification: 50ml

Special effects: high strength, leak proof, anti loosening

Viscosity: 1500~5000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 12.5~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Description: Suitable for most metal surfaces Thixotropic viscosity, good chemical resistance. For locking and sealing of threads up to M20. Permanent thread locking agent, excellent rust and corrosion resistance.

Model: 271 thread locking adhesive

Specification: 50ml

Special effects: high strength, leak proof, anti loosening

Viscosity: 500~2000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 20~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Explanation: Medium viscosity, used for permanent locking and sealing of threads below M36.

Model: 272 thread locking adhesive

Specification: 50ml

Special effects: high strength, leak proof, anti loosening

Viscosity: 5000~12000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 20~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Explanation: Medium viscosity, used for permanent locking and sealing of threads below M36.

Model: 277 thread locking adhesive

Specification: 50ml

Special effects: high strength, leak proof, anti loosening

Viscosity: 4000~7000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 15~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.25mm

Description: It can withstand high temperatures up to 230 ℃ and can be used for quick curing of cylinder head double head thread locking, including fasteners without special surface treatment. It is recommended to use for bolts with a diameter of 1.5 # or less. Heating and tool usage are required during disassembly.

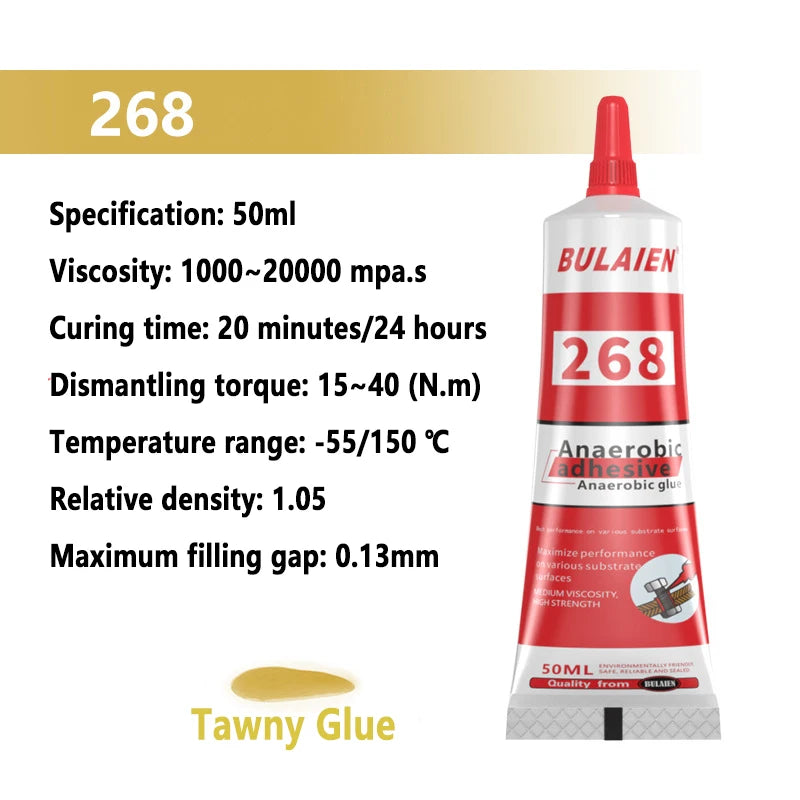

Model: 268 thread locking adhesive

Specification: 50ml

Special effects: high strength, leak proof, anti loosening

Viscosity: 1000~20000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 15~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Explanation: Medium viscosity, used for permanent locking and sealing of threads below M36.

Model: 340 thread locking adhesive

Specification: 50ml

Special effects: high strength, leak proof, anti loosening

Viscosity: 500~2500 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 15~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Description: It can withstand high temperatures up to 150 ℃ and can be used for quick curing of cylinder head double head thread locking, including fasteners without special surface treatment. It is recommended to use for bolts with a diameter of 1.5 # or less. Heating and tool usage are required during disassembly.

Specification: 50ml

Viscosity: 500~2500 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 15~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Specification: 50ml

Viscosity: 2000~7000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 10~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Model: 290 thread locking adhesive

Specification: 50ml

Special effects: Medium strength, penetration grade, detachable

Viscosity: 10~25 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 2.5~205 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Description: Used for locking and sealing of assembled M2-M12 threads. It can also be used for sealing welds, casting sand holes, and other micropores below 0.254mm. To prevent thread rust and corrosion, local heating and tool use are required during disassembly.

Model: 609 Cylindrical Component Retaining Adhesive

Specification: 50ml

Special Effects: High Intensity Universal Type

Viscosity: 100~300 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 10~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Explanation: Fast curing, can be used on inert surfaces, good oil tolerance. Easily removable, can be used on slightly oil-contaminated work surfaces. For locking and sealing of threads up to M20.Medium strength, suitable for transition and interference fits. Fixed key and shaft bearing fits, small motor rotor shafts, bushings. Repair worn holes, shaft mating parts or overfitting parts. The optimal radial filler gap is 0.13mm or less, providing 21MPa shear strength after 24 hours.

Model: 620 Cylindrical Component Retaining Adhesive

Specification: 50ml

Special effects: high strength, high temperature resistance

Viscosity: 7000~10000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 20~40 (N.m)

Temperature range: -55/230 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Explanation: High strength, high viscosity, no flow. Hold valve bushings, injection molding machine core bushings, valve bushings, cylinder bushings, keyways, etc. Resistance to high temperature up to 200 ℃, providing shear strength of 19.0N/mm or more to steel.

Model: 638 Cylindrical Component Retaining Adhesive

Specification: 50ml

Special effect: High strength, fast curing

Viscosity: 2000~10000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 15~50 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.13mm

Explanation: The strong retaining adhesive for dynamic or cyclic loading, for holding shaft-hole fits with a clearance of up to 0.381 mm. Initial curing in 5 minutes..

Model: 648 Cylindrical Component Retaining Adhesive

Specification: 50ml

Special effect: High strength, fast curing

Viscosity: 400~4000mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 20~50 (N.m)

Temperature range: -55/175 ℃

Relative density: 1.08

Maximum filling gap: 0.13mm

Explanation: Can be used in continuous operating temperatures up to 175 ° C Filling gap of 0.1524mm or less. Initial curing within 5 minutes.

Model: 680 Cylindrical Component Retaining Adhesive

Specification: 50ml

Special effects: high strength, medium viscosity, oil resistance

Viscosity: 1000~7000 mpa.s

Curing time: 20 minutes/24 hours

Dismantling torque: 15~40 (N.m)

Temperature range: -55/150 ℃

Relative density: 1.05

Maximum filling gap: 0.23mm

Explanation: Medium viscosity, suitable for clearance fits or interference fits. Holds pipe sleeves, pulleys, gears, rotors. Repair holes, shaft mating parts with overfitting parts in 10 minutes initial cure. Provides greater than 0.7n/mm shear strength on steel after 24 hours. Maximum filler gap is 0.381mm.